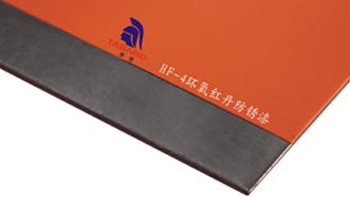

Product Description

It is composed by epoxy resin, red lead, filler and amine curing agent, etc. The paint has good antirust property and good wettability on the metal surface. After formation of the film, the paint has good mechanical strength and strong adhesion. The film is dry quickly and resistant to water and moist.

Design Purpose

It is applicable to steel surface with strong anticorrosion performance, for example, the antirust primer of wet (dry) gas holder, various storage tanks, underwater steel structures, underground pipeline, marine mine structure and equipment and facilities of industrial factory buildings.

Physical Parameters | Color: | Orange |

| Theoretical spreading rate | 150g/m2 (calculated by 40μm dry film, excluding loss) |

| Specific gravity: | About 2.40 |

| Drying time | 23±2℃: surface dry :2h, hard dry:24h |

| Entirely cured | 23±2℃: 7d. |

| Flash point | Component A: 28℃; Component B: 20℃ |

| Storage period | 12 months |

Construction Instruction | Mixing ratio | Component A: Component B =30:1.5 |

Maturing time | 23±2℃: 30min | |

Service life | 23±2℃: 6h | |

Construction method | High pressure siphon spray, air spray, manual brushing, roller painting. | |

Diluent | Diluent for X-7 epoxy coating | |

The largest amount of dilution | <5% | |

Spray orifice | 0.4~0.5mm | |

Spray pressure | About 120~150kg/cm2 | |

Tool washing | Diluent for X-7 epoxy coating. | |

Film coating thickness | Wet film: 70μm, dry film:40μm | |

Coating interval | 25℃: minimum 2h, maximum 2d | |

Surface treatment | The steel surface shall be treated with rust cleaning, oil removal and have no dust and water mark. In general case, a handful of rust and corrosion on the steel surface is allowable, however, loose oxide skin is not allowable; according to special requirements, rust cleaning shall reach Class Sa2.5 of Swedish de-rusting standard, or Class St3 for manual or power tool de-rusting. The surface must be with no rust and corrosion, no grease, no water mark and no floating dust. | |

Construction condition | Two-component paint must be fully stirred well, mixed accurately as per the stipulated quality and put into construction after 30min rest. Room temperature: 5℃~+40℃ Relative humidity: ≤85%. Object surface shall be dry, if there is water, the film is easy to blister. Construction shall not be done under condition of strong wind, heavy rain, snow or foggy weather. In hot summer, construction shall be avoided in strong sunlight. | |

| Finishing paint | Various volatile self-dry coatings, curable coatings. |

Packing Specification | Container of 20 liters can load Component A of 30kg, container of4 liters can load Component B of 1.5kg. (Weigh and add Component A as per mixing ratio when in use.) | |

Remarks | Thickness of the film can be modified according to purpose and position of use, however, this will change the spreading rate accordingly, the drying time of dilution amount and repainting shall have intervals. | |

Considerations | *The coating will partly precipitate and demix after a phase of storage, therefore, the paint (Component A) shall be stirred evenly before preparing coating, and then Component B is added and stirred evenly as per mixing ratio. *The prepared coating shall be matured and put into construction after 30min rest. *If chlorosulfonated coating or high chlorinated coating are used as the subsequent assorted coating, the subsequent coating can be conducted only after the surface drying of the coating. *The film contains red lead and shall not be used for enclosed space with requirements of distortion correction by flame to avoid lead poisoning. | |

Safety guide | Please pay attention to the security issues on the packaging. In addition, relevant Safety guide codes of nation or specified by the local government shall be followed. Avoid inhaling solvent vapors and painting mist for long term, skin and eye may not contact with the product. Forced ventilation shall be provided when applying the paint in confined spaces or stagnant air, although in good ventilation, protection tools shall be worn. | |

Annotation | *Relevant data in this instruction is obtained from laboratory, the actual product may be slightly different from it; *If above data is changed, the data is based on the latest instruction, without prior notification. | |

Primer

Primer

0086-20-37398166

0086-20-37398166 tabarda@gztabard.com

tabarda@gztabard.com Production base: Huadu District, Guangzhou, North Xing Zhen Xin Industrial Park Tamura

Production base: Huadu District, Guangzhou, North Xing Zhen Xin Industrial Park Tamura