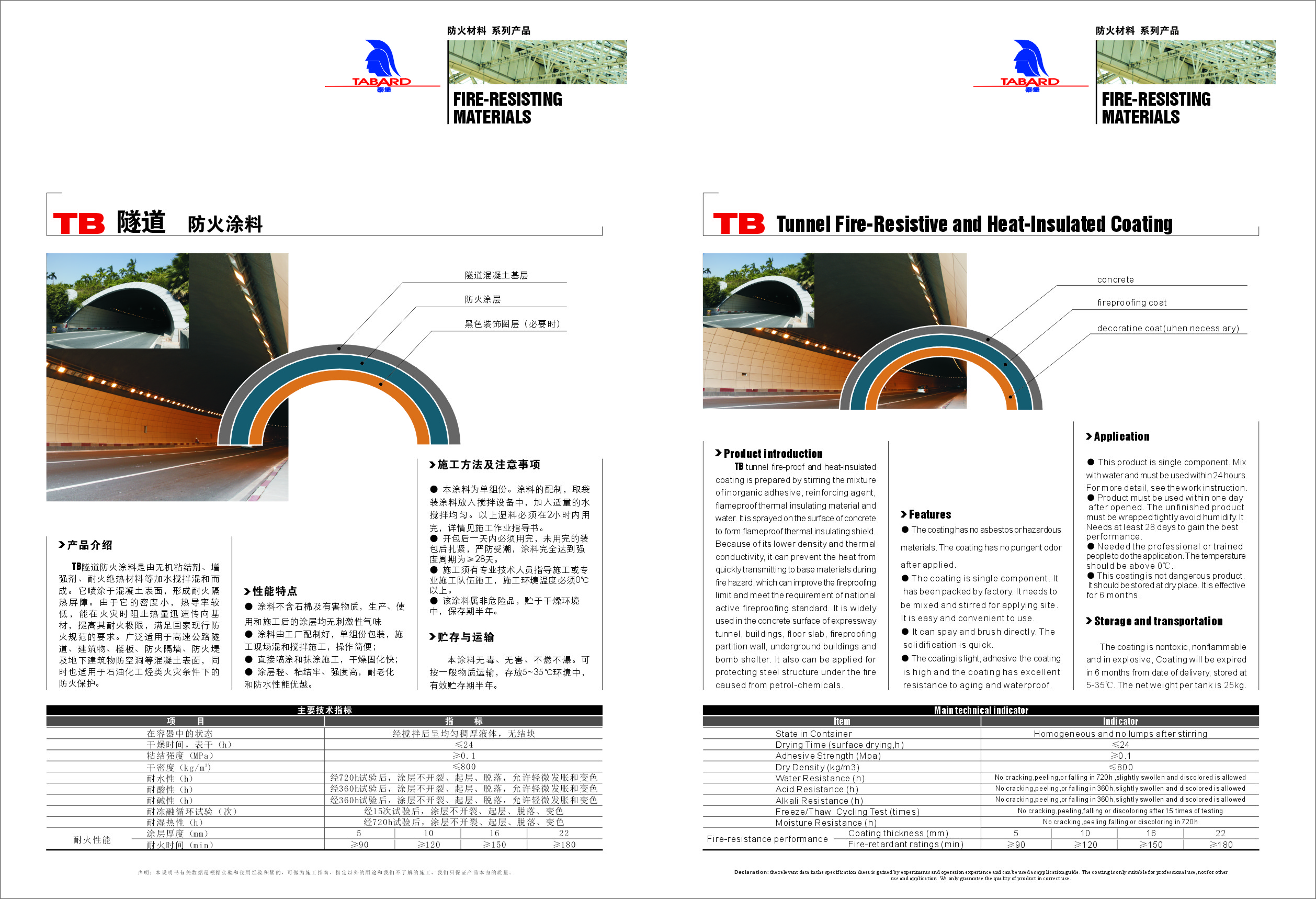

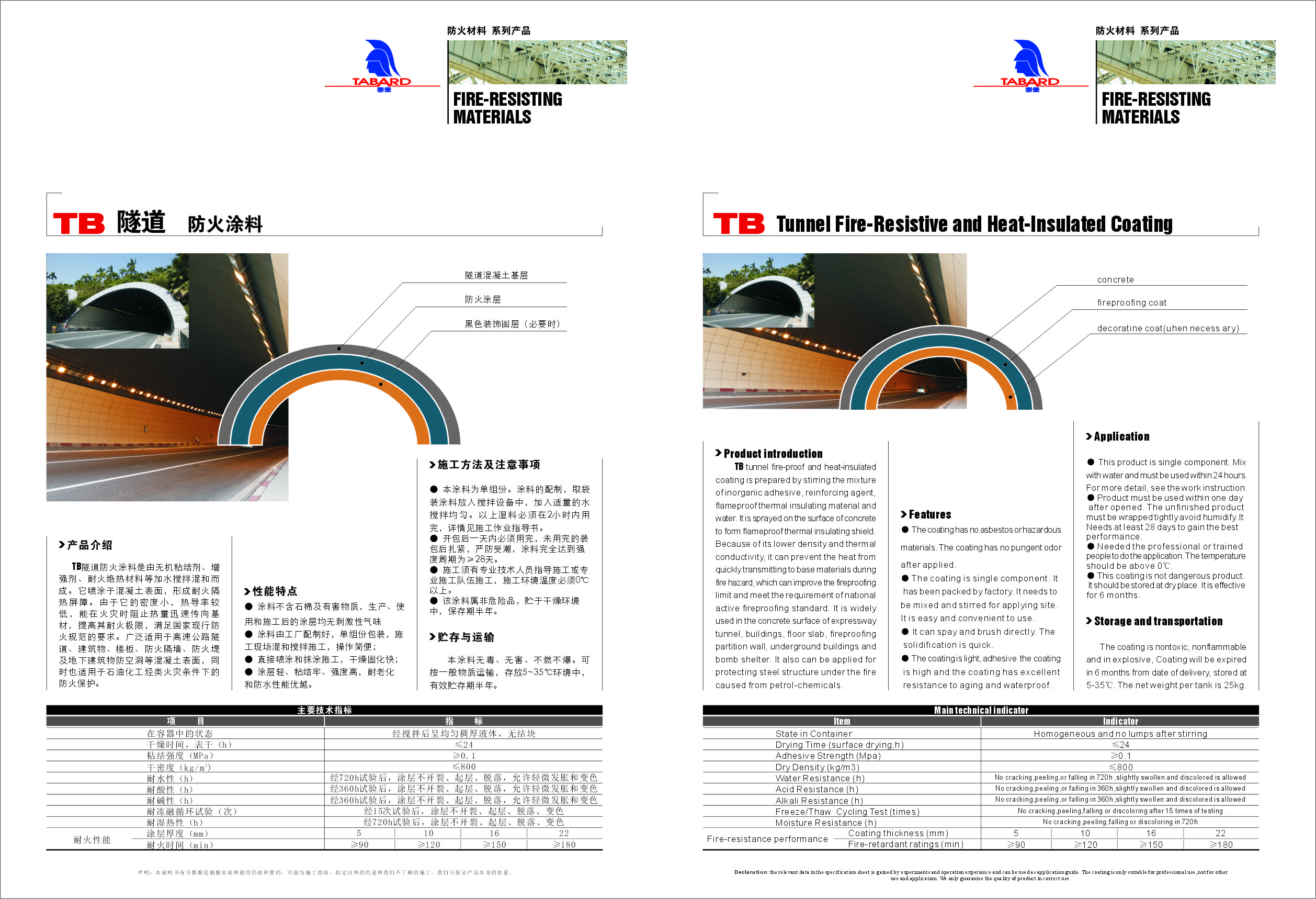

Product introduction

TB tunnel fireproof and heat-insulated coating is prepared by stirring the mixture of inorganic adhesive,reinforcing agent. flameproof thermal insulating material and water.

It is sprayed on the surface of concrete to form flameproof thermal insulating shield. Because of its lower density and thermal conductivity, it can prevent the heat from quickly transmitting to base materials during fire hazard, which can improve the fireproofing limit and meet the requirement of national active fireproofing standard. It is widely used in the concrete surface of expressway tunnel,buildings,floor slab, fireproofing partition wall, underground buildings and bomb shelter. It also can be applied for protecting steel structure under the fire caused from petrol-chemicals.

Features

The coating has no asbestos or hazardous materials. The coating has no pungent odor after applied.

The coating is single component. It has been packed by factory. It needs to be mixed and stirred for applying site.

It is easy and convenient to use.

It can spay and brush directly. The solidification is quick.

The coating is light, adhesive the coating is high and coating has excellent resistance to aging and waterproof.

Aoolication

This product is single component. Mix with water and must be used within 24 hours. For more detail, see the work instruction.

Product must be used within one day after opened. The unfinished product must be wrapped tightly avoid humidify.

It needs at least 28 days to gain the best performance.

Needed the professional or trained people to do the application. The temperature should be above 0℃

This coating is not dangerous product. It should be stored at dry place. It is effective for 6 months.

Storage the transportation

The coating is nontoxic, nonflammable and in explosive, Coating will be expired in 6 months from date of delivery, stored at 5-35℃.The net weight per tank is 25kg.

Main technical indicator

| Item | Indicator | ||||

| State in Container | Homogeneous and no lumps after stirring | ||||

| Drying Time (surface drying,h) | <=24 | ||||

| Adhesive Strength (Mpa) | >=0.1 | ||||

| Dry Density (kg/m3) | <=800 | ||||

| Water Resistance (h) | No cracking,peeling,or falling in 720h,slightly swollen and discolored is allowed | ||||

| Acid Resistance (h) | No cracking,peeling,or falling in 360h,slightly swollen and discolored is allowed | ||||

| Alkali Resistance (h) | No cracking,peeling,or falling in 360h,slightly swollen and discolored is allowed | ||||

| Freeze/Thaw Cycling Test (times) | No cracking,peeling,falling or discoloring after 15 times of testing | ||||

| Moisture Resistance (h) | No cracking,peeling,falling or discoloring in 720h | ||||

| Fire-resistance performance | Coating thickness(mm) | 5 | 10 | 16 | 22 |

| Fire-retardant ratings(min) | >=90 | >=120 | >=150 | >=180 | |

Declaration:the relevant data in the specification sheet is gamed by experiments and operation and can be use dasapplication guide.The coating is only suitable for professional use,not for other use and application. We only guarantee the quality of product in correct use .

Primer

Primer

0086-20-37398166

0086-20-37398166 tabarda@gztabard.com

tabarda@gztabard.com Production base: Huadu District, Guangzhou, North Xing Zhen Xin Industrial Park Tamura

Production base: Huadu District, Guangzhou, North Xing Zhen Xin Industrial Park Tamura